MIL-DTL-8971F

4.5 Conformance inspections. Conformance inspections are inspections of production

products for delivery. Unless otherwise specified in the contract or purchase order, conformance

inspection samples from each production lot shall be subject to the inspections shown in table IV

in accordance with the procedures in 4.6. A production lot is defined as an indefinite quantity of

electrodes, which were manufactured at the same location, from the same mix of graphite

material, and in accordance with the same manufacturing processes and procedures, and which

were subjected to the manufacturer's purification process at the same time. The manufacturer

shall mark lots of electrodes with a single unique lot identifier, which is traceable back to a single

mix of raw graphite material. For groups I and II inspections (see table IV), samples of sufficient

size to be statistically relevant shall be selected in accordance with ASQ Z1.4 for general

inspection level I. For group III inspections, a random sample of 500 disk electrodes and 50 rod

electrodes shall be selected for testing. When practical, the inspections shall be performed in the

order shown in table IV. Units passing group I inspections may be reused in groups II and III

inspections, provided they have not been contaminated. Groups II and III inspections are each

considered destructive testing and the units tested on either test shall not be reused.

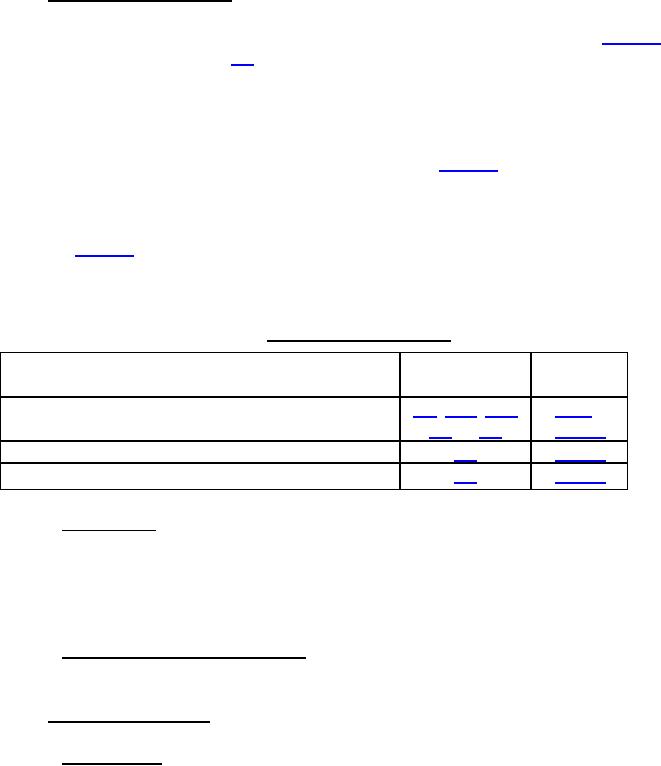

TABLE IV. Conformance inspections.

Requirement

Inspection

Inspections

paragraph

paragraph

Group I:

Material, workmanship, cleanliness,

4.6.1 &

dimensions, and mass

Group II: Impurities

Group III: Accuracy and repeatability

4.5.1 Rejected lots. If an inspection lot is rejected for a feature that may be corrected or

screened, the manufacturer may rework the lot to correct the defects or screen the lot to remove

the defective units and resubmit the lot for reinspection. Such lots shall be separate from new

lots and shall be clearly identified as reinspection lots. New electrode samples shall not be

submitted until the manufacturing defects have been resolved.

4.5.2 Disposition of inspection samples. Product samples that have been subjected to

conformance inspection shall not be delivered on contract or order.

4.6 Methods of inspection.

4.6.1 Examinations. Manufacturer's records and sample electrodes shall be carefully

examined to determine compliance with the specification requirements for materials, dimensions,

workmanship, and cleanliness.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business