MIL-DTL-8971F

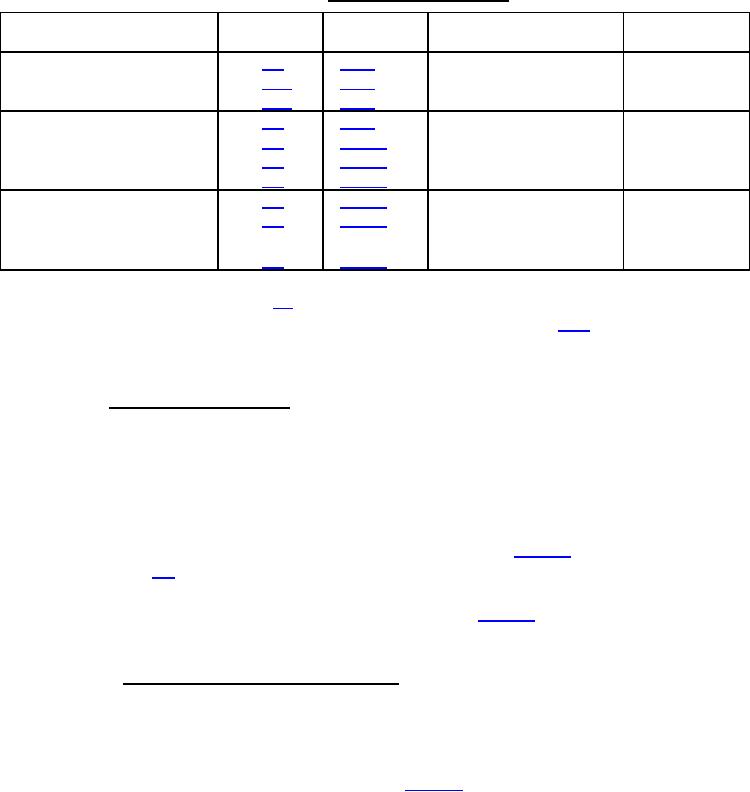

TABLE III. Qualification inspections.

Requirement

Verification

Quantity of disk

Quantity of rod

Inspections

paragraph

paragraph

electrodes

electrodes

Group A: Material 1

-

-

Workmanship

20

20

Cleanliness

20

20

Group B: Dimensions

20

20

Mass

20

20

Density2

20

20

Resistivity2

-

-

Group C: Flexural strength2

-

-

Impurities

40

40

Accuracy and

repeatability

500

50

1

The Group A material inspection consists of an examination of the purity certification for the raw stock material

used to manufacture the electrodes (see 3.2).

2

Designates inspections that may have a non-electrode test specimen requirement (see 4.3.1). When choosing to

use a non-electrode test specimen, include a quantity of non-electrode test specimens that matches the electrode

quantity.

4.4 Qualification inspections. Qualification inspections shall be performed on sample

electrodes and non-electrode test specimens, which were produced with equipment, materials,

procedures and processes normally used in production and which were processed as a single

qualification lot. A qualification lot is defined as an indefinite quantity of electrodes and non-

electrode test specimens, which were manufactured at the same location, from the same mix of

graphite material, and in accordance with the same manufacturing procedures and processes, and

which were subjected to the manufacturer's purification process at the same time. The

qualification samples shall be subjected to the inspections shown in table III in accordance with

the procedures in 4.6. One or more failures shall be cause for denial of qualification. The

qualification inspection samples for each examination and test shall consist of the quantities of

electrodes and non-electrode test specimens as are indicated in table III. Inspection samples that

are not damaged or contaminated in earlier inspections may be used in later inspection tests.

4.4.1 Qualification inspection responsibility. The manufacturer shall be responsible for

the performance of all qualification inspections. Electrode accuracy and repeatability tests and

calculations shall be performed at a laboratory approved by the qualifying activity. The

manufacturer may use his own or other suitable facilities for the performance of all other

qualification inspections, unless disapproved by the qualifying activity. When practical, the

inspections shall be performed in the order shown in table III. Units passing group A and B

inspections may be reused in subsequent inspections of the same qualification, provided they

have not been broken or contaminated. Group C inspections are considered destructive testing

and the units tested shall not be reused.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business